1.Features:

(1). CNC 5-axis drilling tapping machining center, is a Japanese design, Chinese

OEM produce machine.

(2). The inverted Y-shaped column with a wider span of the joint surface improves the rigidity of the machine.

(3). Equipped with cradle turntable, the parts can be installed at one time to automatically, efficiently and accurately complete the processing of complex processes such as inclined plane and curved surface.

(4). Main structure

Bed(X,Y,Z axis):

Bed and table materials select high strength cast iron, resin sand molding.

The high-precision guideway support structure is adopted, and the position and number of high-bearing sliders are rationally arranged

on each linear guideway according to the mechanical principle, so that the machine can obtain high rigidity and long-term stable accuracy.

The transmission system adopts AC servo motor to drive the heavy load ball screw to rotate and realize the axial linear reciprocating move ment.

Cradle turntable (A/C axis):

A/C axis is driven by DD motor direct drive, no indirect mechanical structure transmission, so that the positioning accuracy and repeated

positioning accuracy of the machine can reach the best state; The cradle turntable does not need to be equipped with hydraulic equipment and uses compressed gas to drive the brakes. Use constant temperature oil cooling, so that the work is more efficient.

(5). 3 axes THK linear guideways. 3 axes P4 bearings, THK C3 ball screws.

(6). A axis with pneumatic brake way.

(7). Spindel speed 12000/15000rpm available.

2.Main Parameters

DESCRIPTION | UNIT | 5-DTC-260 |

Table | X,Y,Z-axes travel | mm | 600x450x330 |

Cradle turntable size | mm | φ260 |

Table load | kg | 60 |

Max. swing dia. of workpiece | mm | φ400 |

Spindle | Taper |

| BT30 |

Speed | rpm | 20000 |

Motor power | kW | 5.5 |

Rated/Max. torque | Nm | 11/22 |

Spindel nose to table surface | mm | 55-385 |

A axis | Travel (tilting) | Degree | ±120° |

Max. speed | rpm | 189 |

Rated torque | Nm | 259 |

Positioning accuracy | Arc.sec | ±8 |

Re-positioning accuracy | Arc.sec | 5 |

C axis | Travel | Degree | 360° |

Max. speed | rpm | 386 |

Rated torque | Nm | 122 |

Positioning accuracy | Arc.sec | ±8 |

Re-positioning accuracy | Arc.sec | 5 |

Feeding | X/Y,/Z axis rapid speed | m/min | 24/24/24 |

X/Y/Z axis cutting speed | mm/min | 1-12000 |

Accuracy | X,Y,Z-axes positioning accuracy | mm | 0.010 |

X,Y,Z-axes re-positioning accuracy | mm | 0.005 |

Tool magazine | Type |

| Arm type |

Capacity | T | 21 |

Others | Overall dimensions | mm | 2350x2000x2750 |

Weight | kg | 3300 |

3.Main Configurations

NO. | NAME | BRAND |

1 | CNC controller | SYNTEC |

2 | Ball screw | THK Japan |

3 | Screw bearing | NSK/NACHI Japan |

4 | Linear guideway | THK Japan |

5 | Spindle | Taiwan |

6 | Cradle turntable | Taiwan |

7 | 3-axis motor | SYNTEC |

8 | Main parts for pneumatic system | China |

9 | Main parts for lubrication system | China |

10 | Main electric parts | China |

11 | Spindle oil cooler | JOY |

12 | Heat exchange | JOY |

13 | Tool magazine | OKADA |

14 | Tool presetter TS27R | RENISHAW |

15 | Internal steel cover | China |

16 | Water pump | China |

17 | Full guard (cover) | ORIENT |

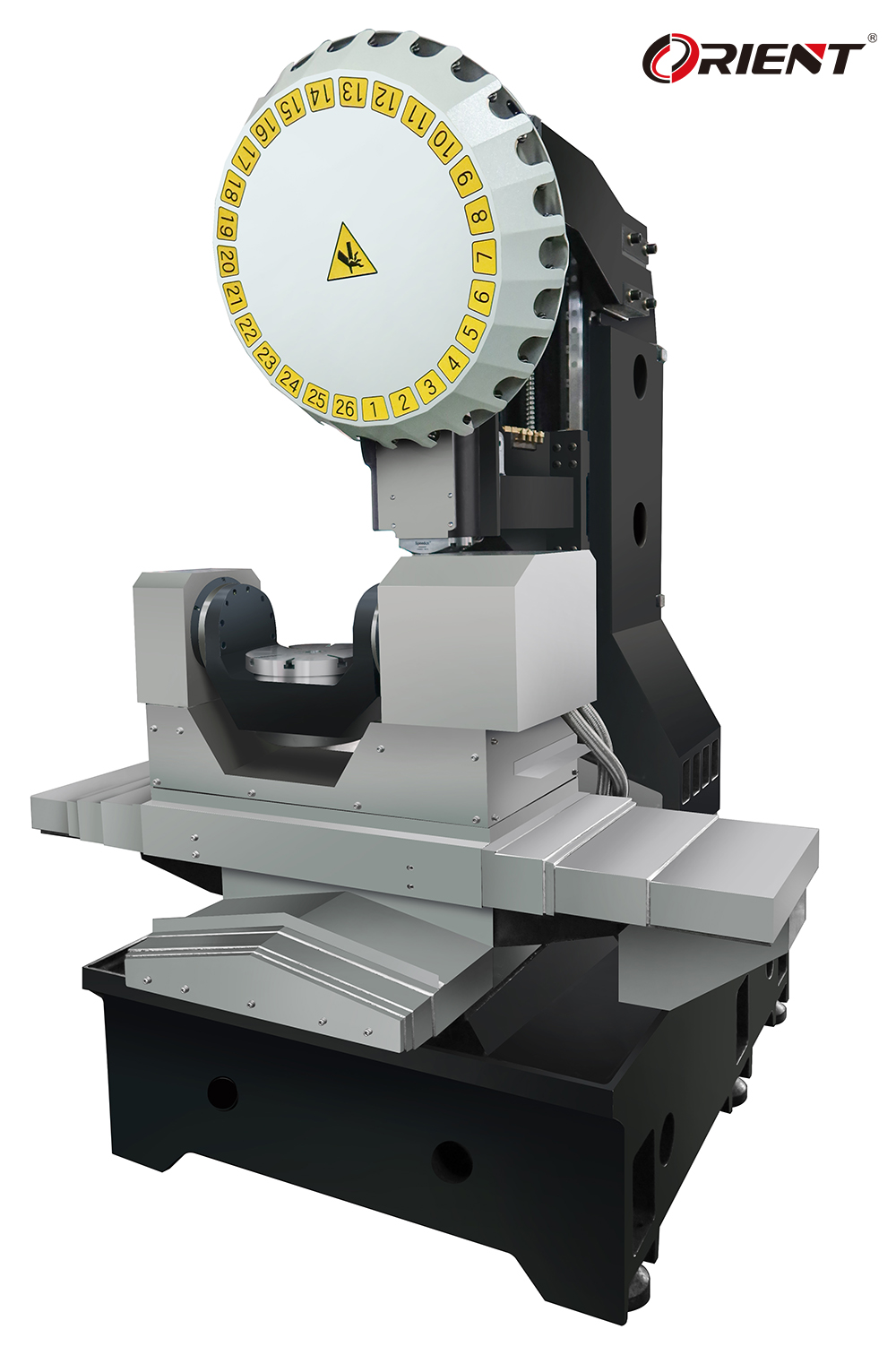

4.Machine Photos