1.Features

(1). Innovative design

Designed in Germany, produced by Chinese OEM. The most ideal and high cost performance of 5-axis processing of the composite machining center.

(2). Main structure

It adopts a five-axis bridge-type vertical frame layout. The high-rigidity bed and the column form a U-shaped frame structure. The bed, column, beam, slide, ram and other large parts are all made of high-strength Meehanite castings. These large parts are designed with the aid of 3D computer software, with reasonable arrangement of ribs and perfect heat treatment process to eliminate residual stress. Ensure that the whole machine has sufficient strength, high rigidity.

(3). Control system

Equipped with SIEMENS ONE controller and drives, it’s with complete function and simple operation; The standard is with communication interface, UF interface and relevant software, as well as DNC on-line processing function.

Optional HEIDENHAIN TNC640 controller.

(4). Drive system

The Y-axis guideway adopts the Japanese THK 45mm ultra-wide roller linear guideway, and the X and Y-axis guideways adopt the Japanese THK 40mm ultra-wide roller linear guideway. Long service life, interchangeability, excellent servo drive performance, improve the precision and precision stability of the machine tool.

The X, Y, Z axis servo motors are directly connected with the Taiwan HIWIN high-precision ball screws through elastic couplings, reducing intermediate links and realizing gap-free transmission, flexible feeding, accurate positioning and high transmission precision.

The Z-axis servo motor has an automatic brake function. In the case of power failure, the automatic brake can hold the motor shaft tightly so that it cannot rotate, which plays a role in safety protection.

A,C-axes servo motors are directly driven, which reduces the transmission error, realizes high-precision transmission, accurate positioning and high transmission precision.

(5). Spindle

The spindle adopts Taiwan cells 20000rpm direct-drive coolant through spindle type electro-spindle, which has high precision and high rigidity. The spindle bearing adopts NSK bearing (P4 grade). After the whole set of spindle is assembled under constant temperature conditions, it passes the dynamic balance correction and running-in test, which improves the service life and reliability of the whole set of spindle. Equipped with a high-precision oil cooler to cool the electric spindle unit, it can realize stepless speed regulation within its speed range. The spindle is controlled by the built-in encoder of the motor, which can realize the function of spindle orientation and rigid tapping.

(6). Tool magazine

The Taiwan horizontal chain type 40 tool magazines are used, which are installed on the inner side of the two columns. When changing tools, the spindle moves to a fixed position for tool changing.

(7). Coolant system

Equipped with cutting fluid filtration, cooling and supply system

Equipped with large-flow cooling pump and large-capacity water tank to fully ensure circulating cooling, cooling pump power: 840W, 66.7L/min large-flow cooling pump, fully provide cooling.

Chip flushing pump power: 1100W, 180L/min large flow chip flushing pump, high pressure flushing and sufficient cooling. The end face of the headstock is equipped with a cooling nozzle and a cleaning air gun to clean the machine tool.

(8). Pneumatic system

The pneumatic two-piece can filter impurities and moisture in the air source, preventing impure gas from damaging and corroding machine tool components. The solenoid valve group is controlled by PLC program to ensure that the spindle loosening, spindle center blowing, spindle clamping and other actions can be completed quickly and accurately.

(9). Detection system

The machine is equipped with the UK Renishaw laser non-contact tool setting probe NC4+F230, designed specifically for use on CNC machine tools and new to Renishaw's range of non-contact products for use on a wide range of machining centers. The NC4 is available as a stationary or stand-alone version, and like all Renishaw non-contact probes, it incorporates the unique MicroHole™ protection system. In addition, the NC4 features PassiveSeal™, an innovative safety protection system that maintains IPX8 sealing performance even if the air supply fails.

Renishaw has now added a range of compact fixed systems to its NC4 range. The F95, F115, F145, F230 and F300 compact NC4 ranges, as well as the NC4+F230 system, set new performance standards with their compact design.

The NC4+F230 system offers excellent real-time tool setting accuracy for applications using small diameter tools.

As with all NC4 systems, this compact range features precision optics as standard, giving it unrivaled performance, making it ideal for smaller machines and those where space is at a premium.

The machine is equipped with Renishaw's OMP60 infrared probe, which is used for part measurement and part set-up on a wide range of machining centers and small to medium-sized multi-purpose machines.

(10). Oil-water separation device

The oil-water separation device is equipped on the tank, through which the oil-water mixture can be quickly separated, and the separated lubricating oil is collected in the designated container, and the cutting fluid is returned to the tank for reuse.

(11). Applications

It is mainly used for box parts, shell parts, molds and other high precision, many processes, complex shape parts of the batch processing, can be in a clamping continuous completion of milling, drilling, reaming, boring, tapping and 3D surface, slope accurate processing, machining to achieve program, mass, shorten the production cycle, so that the users get good economic benefits.

2.Main parameters

DESCRIPTION | UNIT | 5-VMC-650 | ||

Table | Size | mm | φ630 | |

Max. load | kg | 850 | ||

T-slot size | mm | 14 | ||

A/C rated torque | Nm | 2922/840 | ||

A/C braking torque | Nm | 4843/1436 | ||

Working capacity | X,Y,Z-axes travel | mm | 650x800x600 | |

A-axis travel | Degree | +120°/-120° | ||

C-axis travel | Degree | 360° | ||

Distance from spindle nose to table surface | mm | 150-750 | ||

Spindle | Taper | HSK-A63 | ||

Speed | r/min | 40-20000 | ||

Motor power | kW | 31/37.2 | ||

Rated/max. torque | Nm | 100.4/120.5 | ||

Transmission type | Direct drive | |||

Feeding | Rapid feed | X/Y/Z axis | m/min | 48/48/48 |

A/C axis | r/min | 60/90 | ||

Cutting speed | mm/min | 1-10000 | ||

Tool magazine | Type | Straight chain | ||

Capacity | T | 40 | ||

Max. tool dia. | mm | Φ76/Φ125 | ||

Max. tool length | mm | 300 | ||

Max. tool weight | kg | 7 | ||

Positioning accuracy | X,Y,Z-axes | mm | 0.008 | |

A,C-axes | Arc.sec | ±5 | ||

Re-positioning accuracy | X,Y,Z-axes | mm | 0.006 | |

A,C-axes | Arc.sec | 4 | ||

Others | Overall dimensions | mm | 4450x2715x3750 | |

Weight | kg | 15000 | ||

3.Main configurations

NO. | NAME | BRAND | REMARK |

1 | Electro-spindle | SELLS | TAIWAN |

2 | Cradle turntable | HIWIN | TAIWAN |

3 | X,Y,Z-axes ball screws | THK | Japan |

4 | X,Y,Z-axes bearings for ball screw | NACHI | Japan |

5 | Linear guideway | THK | Japan |

6 | Electrical components, solenoid valves, etc. | SMC | Japan |

7 | Servo axis coupling | SANMU | Japan |

8 | Control system | SIEMENS | Germany |

9 | Spindle AC servo motor driver | SIEMENS | Germany |

10 | X-axis servo motor and driver | SIEMENS | Germany |

11 | Y-axis servo motor and driver | SIEMENS | Germany |

12 | Z-axis servo motor and driver | SIEMENS | Germany |

13 | A-axis servo motor and driver | HIWIN/SIEMENS | Taiwan/Germany |

14 | C-axis servo motor and driver | HIWIN/SIEMENS | Taiwan/Germany |

15 | Foundation pads and adjusting bolts | ORIENT | China |

16 | Air conditioner | TONGFEI | China |

17 | Spindle water cooler | TONGFEI | China |

18 | Auto lubrication | BAOTENG | China |

19 | Working lamp | ORIENT | Germany |

20 | Linear scale | FAGOR/HEIDENHAN | Spain/Germany |

21 | X,Y,Z-axes drag chains | SHENGDA | China |

22 | X,Y-axes protection cover | HAIDONG | China |

23 | Water pump | STAIRS | Taiwan |

24 | Electrical components | SCHNEIDER | France |

25 | Tool magazine | CHEN SOUND | Taiwan |

26 | Detection system | RENISHAW | UK |

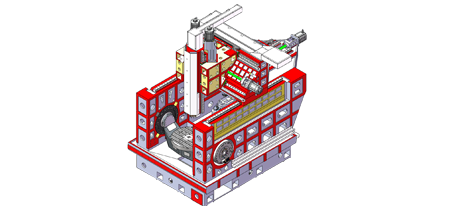

4.Machine Photos