1.Features

(1). Innovative design

Designed in Germany, produced by Chinese OEM. The most ideal and high cost performance of 5-axis processing of the composite machining center.

(2). Main structure

(A). It adopts a five-axis bridge-type vertical frame layout. The high-rigidity bed and the column form a U-shaped frame structure. The bed, column, beam, slide, ram and other large parts are all made of high-strength Meehanite castings. These large parts are designed with the aid of 3D computer software, with reasonable arrangement of ribs and perfect heat treatment process to eliminate residual stress. Ensure that the whole machine has sufficient strength, high rigidity.

(B). The bed adopts integral bed, HT300 resin sand casting, and the large slanting surface of the inner cavity of the bed is matched with the center chip discharge structure, which constitutes a smooth chip discharge method and reduces the accumulation of iron chips during the ma chining process of the whole machine. The bed is not only the support body of the whole machine tool components, but also the support body of the whole machine tool during the handling process.

(C). The column adopts U-shaped, centrally mounted ball screw drive structure, which effectively suppresses the vibration of the machine tool during high acceleration and deceleration; at the same time, the structure completely avoids the shortcomings of poor synchronisation of the double-screw drive, and improves the machining accuracy.

(3). Control system

Equipped with SIEMENS ONE controller and drives, it’s with complete function and simple operation; The standard is with communication interface, UF interface and relevant software, as well as DNC on-line processing function.

Optional HEIDENHAIN TNC640 controller.

(4). Drive system

The X,Y,Z-axes guideways adopt THK 40mm P grade roller linear guideways. In order to make the Y-axis movement of the crossbeam smoother, the axle end of the ball screw is connected to the drive shaft of the AC servomotor with a flexible coupling, and the AC servomotor drives the ball screw directly, with the feed speed adjusted steplessly.

The spindle box moves up and down along the drag plate to achieve Z-axis movement. In order to reduce the weight of the moving parts and effectively increase the rigidity of the moving parts, the spindle box is optimized by finite element analysis. Ear swing rotary table is the standard configuration, which can carry out five-axis linkage machining for blade and other shaped parts; in addition, the fixed table with large load capacity can also be optional. The tool magazine is placed between the two columns above the bed; the electrical cabinet is placed at the side of the column; the hydraulic station is placed at the back of the bed; the whole machine can be lifted after assembly.

(5). Cradle turntable

Dual-axis cradle turntable selected from foreign professional worktable suppliers, the table is a dual-axis ear pendulum rotary table, A, C-axes servo motors direct-drive transmission, reducing transmission errors, to achieve high-precision transmission, positioning accuracy, high transmission accuracy.

The table's A-axis has a large swing angle and a wide machining range, and the C-axis rotates continuously, thus achieving high rotary accuracy.

(6). Spindle

The spindle adopts Taiwan CELLS 20000rpm direct-drive coolant through spindle type electro-spindle, which has high precision and high rigidity. The spindle bearing adopts NSK bearing (P4 grade). After the whole set of spindle is assembled under constant temperature conditions, it passes the dynamic balance correction and running-in test, which improves the service life and reliability of the whole set of spindle. Equipped with a high-precision oil cooler to cool the electric spindle unit, it can realize stepless speed regulation within its speed range. The spindle is controlled by the built-in encoder of the motor, which can realize the function of spindle orientation and rigid tapping.

(7). Tool magazine

Adopting Taiwan flat chain type 40pcs tool magazines,the motor directly drives the tool magazine to rotate, the telescopic pneumatic cylinder is used to realize the forward and backward movement of the tool magazine, and the pneumatic positioning system is used to ensure the accuracy of the spindle tool changing position, and the tool magazine has a high cost performance.

(8). Coolant system; Lubricant system; Hydraulic system

(A). Equipped with cutting fluid filtration, cooling and supply system.

Equipped with large-flow cooling pump and large-capacity water tank to fully ensure circulating cooling, cooling pump power: 840W, 66.7L/min large-flow cooling pump. Chip flushing pump power: 1100W, 180L/min high flow rate chip flushing pump, fully provide cooling.

(B). Equipped with automatic air blowing and cleaning function of spindle taper hole.

At the moment when the tool is released, the air blowing air path is opened, and the air reaches the taper hole through the center of the spindle. The air blowing is always maintained during the tool changing process until the tool changing is completed and the air blowing is interrupted. This function is specially used for blowing off the possible foreign particles on the spindle taper hole and the surface of the tool holder during the tool change process, preventing the intrusion of foreign objects, and keeping the surface clean.

(C). Equipped with spindle constant temperature cooling.

Equipped with an water cooler, the bearings in the spindle are cooled by circulating cooling water.

(D). Machine servo axis automatic lubrication device.

The lubrication of the machine tool guideway is directly supplied by the fixed and quantitative centralized lubrication pump to the moving parts to lubricate the three-coordinate guideway surface: the column-slide guideway surface, the slide seat-slider guideway surface, the slide -ram guideway surface and the lead screw nut. After the machine tool is powered on, the lubricating oil pumped by the lubricating pump motor is injected into the sliding block and ball screw nut of each guide rail through the oil pipe and joint. The timing lubricating device is equipped with an oil level switch. When the lubricating oil level in the oil tank is lower than the set height, the machine tool will alarm. Generally, the tank should be refueled every two weeks or so.

(E). Equipped with low oil level alarm device.

When the oil quantity is insufficient, the low oil level alarm device will detect the signal and transmit it to the system for alarm indication. When adding lubricating oil, according to the seasonal temperature change, choose the oil agent with approximate viscosity value to achieve good lubrication effect, the lubricating oil with too low viscosity may cause the exhaust valve in the pump can not work, thus the pump can not start the pressure. It is recommended to use 68# hydraulic guide oil.

(F). Oil skimmer device.

The tank is equipped with an oil skimmer device, through which the oil-water mixture can be quickly separated, and the separated lubricant is collected in a designated container, and the cutting fluid is returned to the tank for reuse.

(9). Pneumatic system

The pneumatic system of this machine tool uses high-performance components from famous foreign manufacturers. The system mainly blows air to the machine tool's working table, tool magazine cylinder and tool cooling and oil-air lubrication system. And there are detection components and feedback signals, in the pneumatic system work process, real-time monitoring to ensure the stability of the pneumatic system.

The pneumatic two-piece can filter impurities and moisture in the air source, preventing impure gas from damaging and corroding machine tool components. The solenoid valve group is controlled by PLC program to ensure that the spindle loosening, spindle center blowing, spindle clamping and other actions can be completed quickly and accurately.

(10). Machine guard

The machine is equipped with CE safety compliant guards to prevent coolant from splashing and to ensure safe operation and a pleasant appearance. Each guideway of the machine has a protective cover to prevent chips and coolant from entering the machine, and to protect the guideway and ball screw from abrasion and corrosion. The organ guard is added on the upper part of the crossbeam to better protect the guideway and screw.

Equipped with a lighting system for the processing area.

Adopting closed electric cabinet, the electric cabinet adopts air conditioner for heat dissipation to ensure the normal work of electric equipment. The electrical cabinet adopts slot board wiring structure, the component arrangement and wiring is reasonable, neat, beautiful and easy for maintenance. The electrical cabinet is equipped with internal lighting and sockets for debugging. A certain space is reserved in the power box for expanding functions.

Equipped with an oil-water separator.

Equipped with wear-resistant safety glass to ensure the safety of the operator.

(11). Chip removal system

The iron chips produced in the processing fall directly into the protective compartment. The internal slant structure of the protection allows the iron chips to slide smoothly into the chain type conveyor and collect the iron chips in the chip box through the chain plate.

(12). Cleaning system

In order to clean up the iron chips inside the guard in time and to facilitate regular cleaning by the operator, a hand-held high-pressure cleaning water gun is equipped on the side of the guard.

(13). Detection system

The machine is equipped with the UK Renishaw laser non-contact tool setting probe NC4+F230, designed specifically for use on CNC machine tools and new to Renishaw's range of non-contact products for use on a wide range of machining centers. The NC4 is available as a stationary or stand-alone version, and like all Renishaw non-contact probes, it incorporates the unique MicroHole™ protection system. In addition, the NC4 features PassiveSeal™, an innovative safety protection system that maintains IPX8 sealing performance even if the air supply fails.

Renishaw has now added a range of compact fixed systems to its NC4 range. The F95, F115, F145, F230 and F300 compact NC4 ranges, as well as the NC4+F230 system, set new performance standards with their compact design.

The NC4+F230 system offers excellent real-time tool setting accuracy for applications using small diameter tools.

As with all NC4 systems, this compact range features precision optics as standard, giving it unrivaled performance, making it ideal for smaller machines and those where space is at a premium.

The machine is equipped with Renishaw's OMP60 infrared probe, which is used for part measurement and part set-up on a wide range of machining centers and small to medium-sized multi-purpose machines.

(14). Applications

It is mainly used for box parts, shell parts, molds and other high precision, many processes, complex shape parts of the batch processing, can be in a clamping continuous completion of milling, drilling, reaming, boring, tapping and 3D surface, slope accurate processing, machining to achieve program, mass, shorten the production cycle, so that the users get good economic benefits.

2. Main parameters

DESCRIPTION | UNIT | 5-VMC-500 | ||

Table | Size | mm | Φ500 | |

Max. load | kg | 500 | ||

T-slot size | mm | 14 | ||

A-axis rated torque | Nm | 1290 | ||

C-axis rated torque | Nm | 600 | ||

A-axis locking torque | Nm | 2400+1680 | ||

C-axis locking torque | Nm | 2400 | ||

Working capacity | X,Y,Z-axes travel | mm | 500x600x450 | |

A-axis travel | Degree | +120°/-120° | ||

C-axis travel | Degree | 360° | ||

Distance from spindle nose to table surface | mm | 130-580 | ||

Spindle | Taper | HSK-A63 | ||

Speed | r/min | 40-20000 | ||

Motor power | kW | 31/37.2 | ||

Rated S1/Max S6 torque | Nm | 100.4/120.5 | ||

Transmission type | Direct drive | |||

Feeding | Rapid feed | X/Y/Z axis | m/min | 32/32/32 |

A/C axis | r/min | 60/100 | ||

Cutting speed | mm/min | 1-12000 | ||

Tool magazine | Type | Flat chain | ||

Capacity | T | 40 | ||

Max. tool dia. | mm | Φ76/Φ125 | ||

Max. tool length | mm | 300 | ||

Max. tool weight | kg | 7 | ||

Positioning accuracy | X,Y,Z-axes | mm | 0.008 | |

A,C-axes | Arc.sec | 10 | ||

Re-positioning accuracy | X,Y,Z-axes | mm | 0.006 | |

A,C-axes | Arc.sec | 4 | ||

Others | Overall dimensions | mm | 4122x2500x3250 | |

Weight | kg | 12000 | ||

3.Main configurations

NO. | NAME | BRAND | REMARK |

1 | Electro-spindle | CELLS | Taiwan |

2 | Rotary table | HIWIN | Taiwan |

3 | X ,Y,Z-axes ball screws | HIWIN | Taiwan |

4 | X,Y,Z-axes bearings for ball screw | NSK | Japan |

5 | Linear guideway | THK | Japan |

6 | Pneumatic components, solenoid valves, etc. | SMC | Japan |

7 | Coupling | Milk pully | Japan |

8 | Control system | SIEMENS | Germany |

9 | Spindle AC servo motor driver | SIEMENS | Germany |

10 | X-axis servo motor and driver | SIEMENS | Germany |

11 | Y-axis servo motor and driver | SIEMENS | Germany |

12 | Z-axis servo motor and driver | SIEMENS | Germany |

13 | A-axis servo motor and driver | SIEMENS | Japan |

14 | C-axis servo motor and driver | SIEMENS | Japan |

15 | Foundation pads and adjusting bolts | ORIENT | China |

16 | Air conditioner | TONGFEI | China |

17 | Spindle water cooler | TONGFEI | China |

18 | Auto lubrication | BAOTENG | China |

19 | Working lamp | ONLION | Germany |

20 | Linear scale | FAGOR/HEIDENHAN | Spain/Germany |

21 | X ,Y,Z-axes drag chain | SHENGDA | China |

22 | X,Y-axes protection covers | HAIDONG | China |

23 | Water pump | STAIRS | Taiwan |

24 | Electrical components | SCHNEIDER | France |

25 | Tool magazine | CHEN SOUND | Taiwan |

26 | Detection system | RENISHAW | UK |

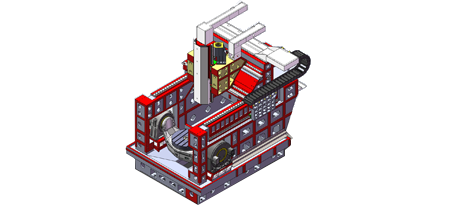

4.Machine Photos