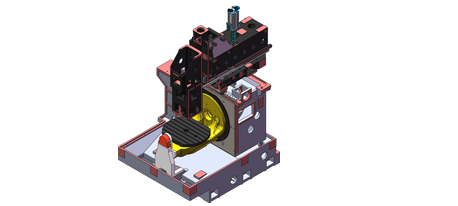

1.Features

(1). Innovative design

Designed in Germany, produced by Chinese OEM. The most ideal and high cost performance of 5-surface processing of the composite machining center.

(2). Main structure

Five-surface frame layout, column and bed integration design. The bed, column, sliding seat, sliding plate and other large parts are all made of high-strength Meehanite castings. These large parts are optimized and designed with 3D computer software. The ribs are arranged reasonably and have a complete heat treatment process to eliminate residual stress. Ensure that the whole machine has sufficient strength and high rigidity.

(3). Control system

Equipped with SIEMENS 828D control system and drives, it’s with complete function and simple operation; The standard is with communication interface, UF interf

ace and relevant software, as well as DNC on-line processing function.

Optional FANUC 0I-MF PLUS (1) controller.

(4). Drive system

X,Y,Z-axes adopt HIWIN 35mm roller linear guideways, which has small friction and wear, high positioning accuracy and sensitivity, small vibration on high speed, long service life, interchangeability, as well as excellent servo drive performance, improving machine accuracy and stability.

X,Y,Z-axes servo motors connect with Taiwan high precision ball screws directly by elastic coupling, realizing gap-free drive, flexible feed, accurate positioning and high transmission accuracy.

Z axis servo motor is with self braking function, in the case of power failure, it can brake automatically and hold the motor shaft tightly, offering safety protection.

B,C-axes servo motors direct drive transmission, reducing transmission error, achieving high-precision transmission, accurate positioning, high transmission accuracy.

(5). Spindle

Spindle adopts Taiwan 12000rpm direct connection spindle with high precision and rigidity (the highest speed of spindle is10000rpm). P4 grade NSK bearing is used for spindle specially. The spindle is assembled under constant temperature and then pass through dynamic balance calibration and running test, improving the whole spindle’s service life and reliability. The high-precision oil cooler is equipped to cool the electric spindle unit, and the stepless speed regulation can be realized in the range of its speed. The spindle is controlled by the built-in encoder of the motor, which can realize the spindle orientation and rigid tapping function.

Optional HSK-A63-20,000rpm electro-spindle.

(6). Tool magazine

The Taiwan disc type 24pcs tool magazine is installed on the side of the column. When the tool is changed, the magazine is driven and positioned by the roller cam mechanism. After the spindle reaches the tool change position, the tool changer (ATC) is used to complete the action of tool changing. ATC is a hobbing cam mechanism. After preloading, it can run at high speed and no noise, making the tool change process fast and accurate.

(7). Cradle turntable

The table is a two-axis single-arm rotary table, B, C-axes torque motors direct drive transmission, reducing transmission errors, to achieve high-precision transmission, positioning accuracy, high transmission accuracy.

(8). Coolant system

Large flow coolant pump and large volume water tank are equipped to ensure circulation cooling, power of coolant pump:840W, 66.7L/min large flow coolant pump supplies the cooling fully. Spindle end is equipped with cooling nozzle, it can be either water cooling or air cooling, and can be switched at will. Air gun is equipped for cleaning the machine.

(9). Pneumatic system

Pneumatic two-piece can filter the impurity and moisture in the air source and prevent the damage and corrosion of machine parts caused by impure gas. Electromagnetic valve is controller by PLC program which can make sure the actions can be finished quickly and correctly, such as spindle releasing the tool, spindle blowing, spindle clamping tool etc.

(10). Machine guard

The machine guards conform to safety standard, not only prevents coolant splash, but also ensures safe operation, and the appearance is beautiful. Every guideway is equipped with protection cover which can prevent chips, coolant from damaging guide ways and ball screws.

(11). Lubrication system

Linear guideways and ball screws are all centralized auto lubrication, each node is equipped with a quantitative oil separator which will inject the oil to lubricating parts quantitatively and regularly ensuring uniform lubrication and effectively reducing friction resistance, movement accuracy is improved, the service life of ball screws and guide ways are ensured.

(12). Chip removal system

The iron chips produced in the processing fall directly into the protective compartment. The internal slant structure of the protection allows the iron chips to slide smoothly into the chain type conveyor and collect the iron chips in the chip box through the chain plate.

(13). Detection system

Machine can be equipped with Renishaw's TS-27R contact tool setter and OMP60 probe. Among them, TS-27R can perform tool setting and breakage detection; OMP60 can measure the machining accuracy of processed workpieces online.

(14). Applications

It is mainly used for box parts, shell parts, molds and other high precision, many processes, complex shape parts of the batch processing, can be in a clamping continuous completion of milling, drilling, reaming, boring, tapping and 3D surface, slope accurate processing, machining to achieve program, mass, shorten the production cycle, so that the users get good economic benefits.

2.Main Parameters

DESCRIPTION | UNIT | 5-VMC-500(BC)(3+2) | |||

Table | Table size | mm | φ630x500 | ||

Max. loading | kg | 200 | |||

T-slot size | mm | 7-14-63 | |||

Working capacity | X,Y,Z-axes travel | mm | 500x450x400 | ||

B-axis travel | Degree | -5° /+110° | |||

C-axis travel | Degree | 360° | |||

Distance from spindle end to table surface | mm | 150-550 | |||

Spindle | Taper | BBT40 | HSK-A63 | ||

Speed | r/min | 40-10000 | 40-20000 | ||

Motor power | kW | 7.5 | 20/30 | ||

Rated/Max. torque | Nm | 38/57 | 30.7/46 | ||

Transmission type | Direct drive | Electro-spindle | |||

Feeding | Rapid feed | X/Y/Z axis | m/min | 36/36/36 | |

B/C axis | r/min | 6/6 | |||

Cutting speed | mm/min | 1-30000 | |||

Tool magazine | Type | Disc type | |||

Capacity | T | 24 | |||

Max. tool size | mm | φ150x300 | |||

Positioning accuracy | X,Y,Z-axes | mm | 0.012 | ||

B,C-axes | Arc.sec | 28 | |||

Re-positioning accuracy | X,Y,Z-axes | mm | 0.01 | ||

B,C-axes | Arc.sec | 16 | |||

Others | Overall dimensions | mm | 3300x3500x3000 | ||

Weight | kg | 6000 | |||

3.Main configurations

NO. | NAME | BRAND | REMARK |

1 | Spindle | KENTURN | Taiwan |

2 | Cradle turntable | HIWIN | Taiwan |

3 | X,Y,Z-axes ball screws | THK | Japan |

4 | X,Y,Z-axes bearings for ball screw | NACHI | Japan |

5 | Linear guideway | THK | Taiwan |

6 | Electrical components, solenoid valves, etc. | SMC | Japan |

7 | Servo axis coupling | SANMU | Japan |

8 | Control system | SIEMENS | Germany |

9 | Spindle AC servo motor and driver | SIEMENS | Germany |

10 | X-axis servo motor and driver | SIEMENS | Germany |

11 | Y-axis servo motor and driver | SIEMENS | Germany |

12 | Z-axis servo motor and driver | SIEMENS | Germany |

13 | B-axis servo motor and driver | HIWIN/SIEMENS | Taiwan/Germany |

14 | C-axis servo motor and driver | HIWIN/SIEMENS | Taiwan/Germany |

15 | Leveling block and bolts | ORIENT | China |

16 | Air conditioner | TONGFEI | China |

17 | Spindle oil cooler | TONGFEI | China |

18 | Auto lubrication | BIJUR | China |

19 | Working lamp | ONLION | Germany |

20 | Linear scale | FAGOR | Spain |

21 | X,Y,Z-axes drag chain | BONA | China |

22 | X,Y-axes protection covers | HAIDONG | China |

23 | Water pump | STAIR | Taiwan |

24 | Tool setting probe | RENISHAW | UK |

25 | Electrical components | SCHNEIDER | France |

26 | Tool magazine | OKADA | Taiwan |

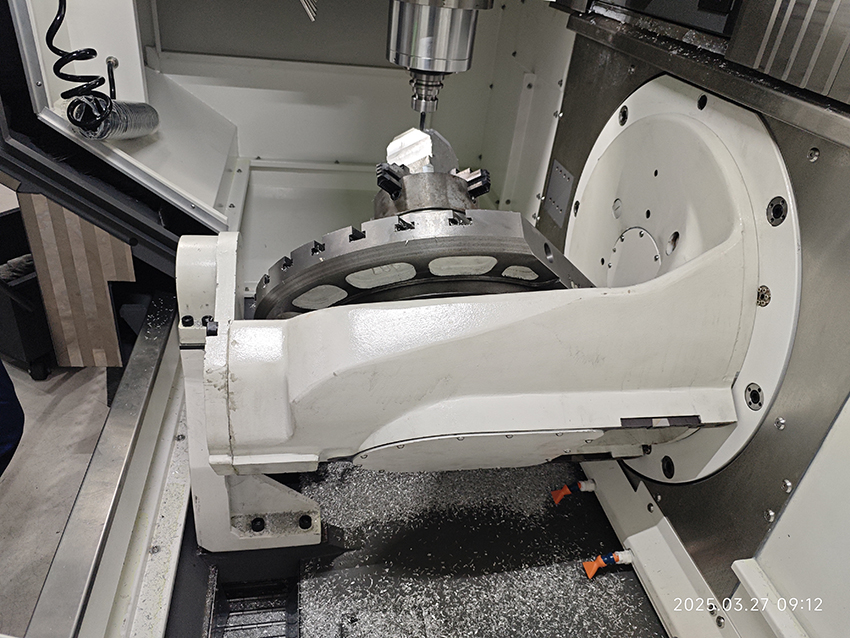

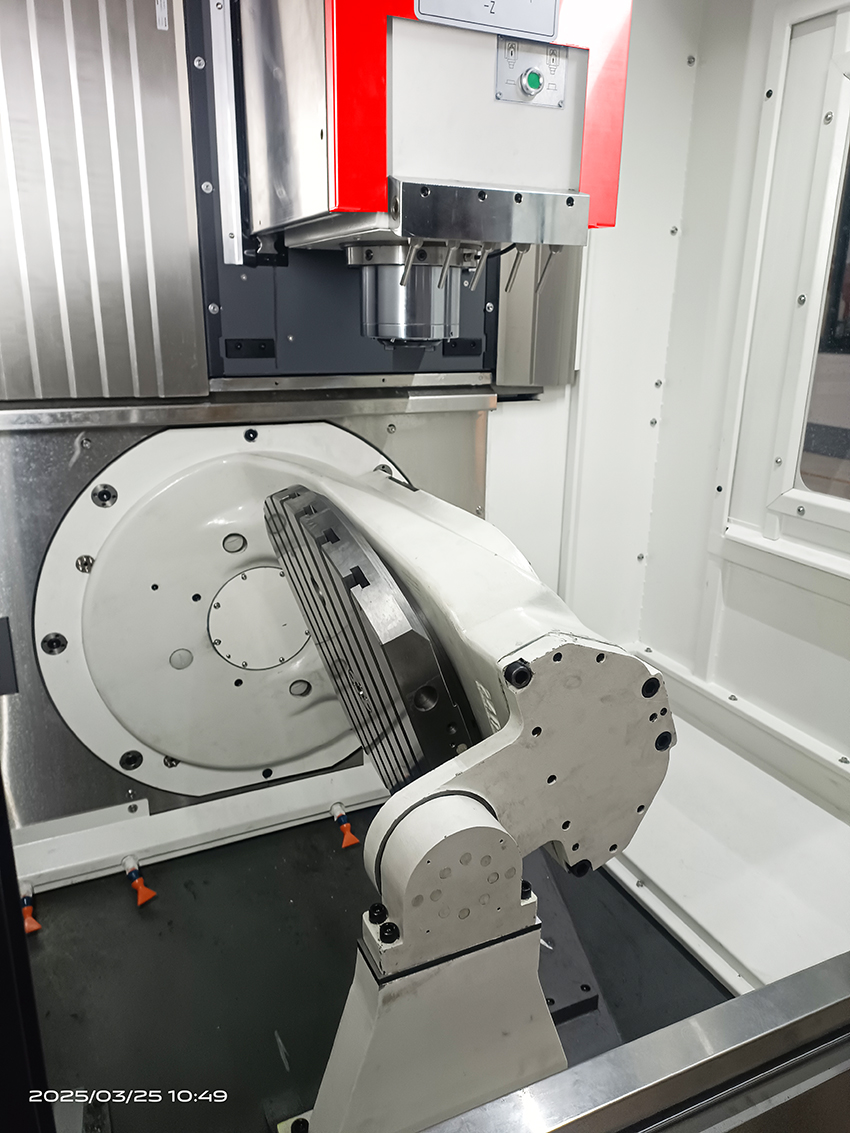

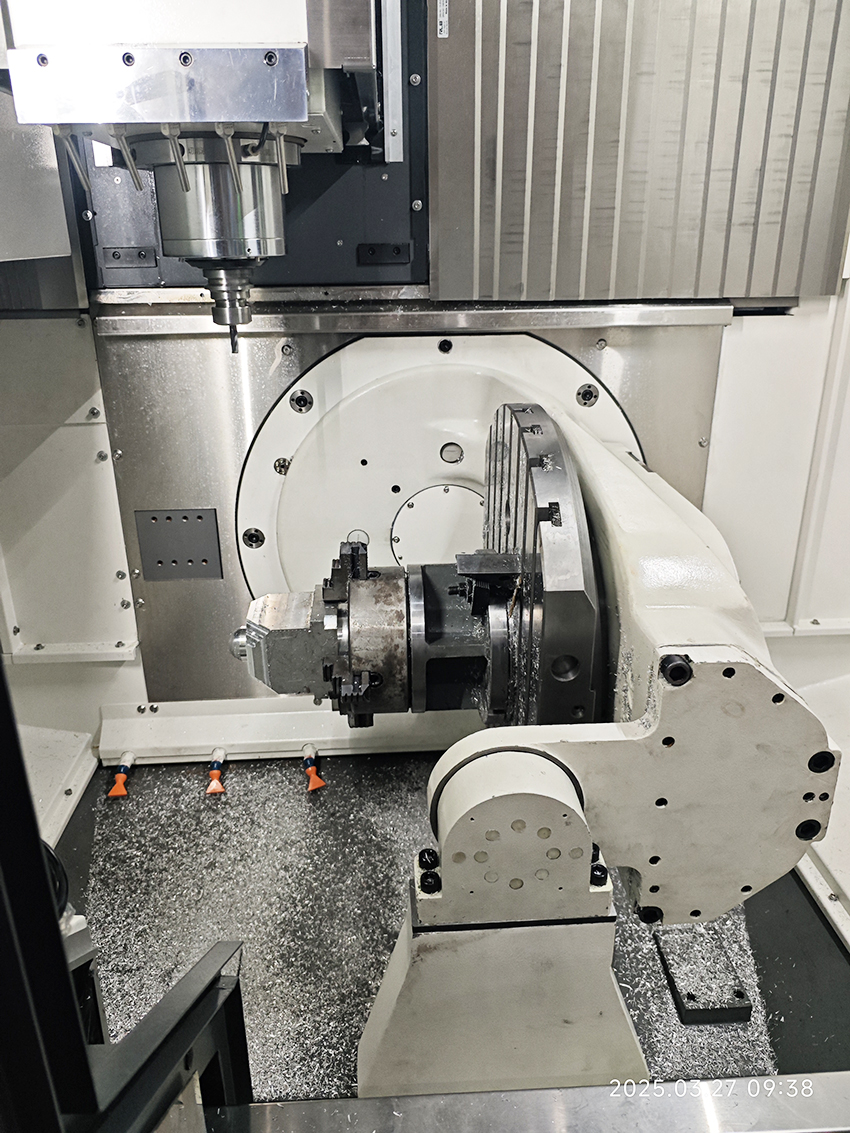

4.Machine Photos